We provide a full range of engineering and production services to the automotive industry. As a client-focused solutions provider, our engineers work as an extension of our client’s own engineering department.

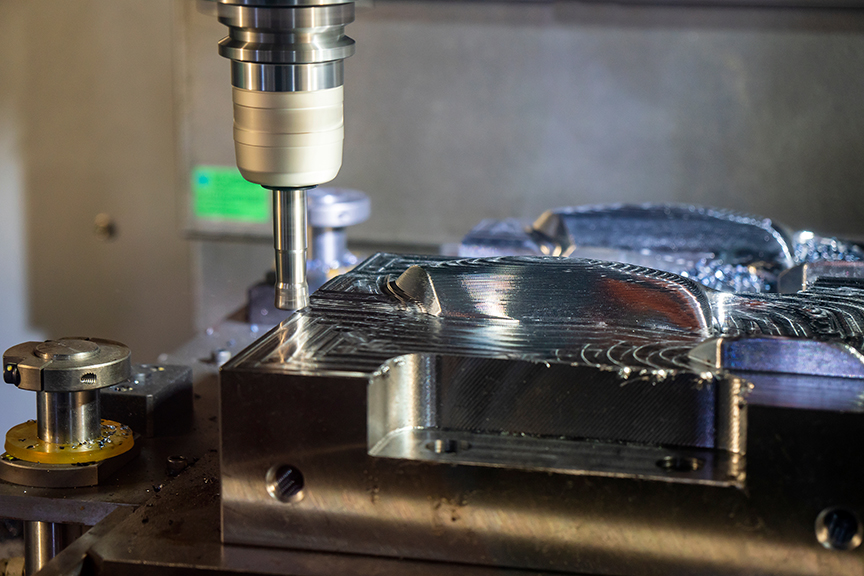

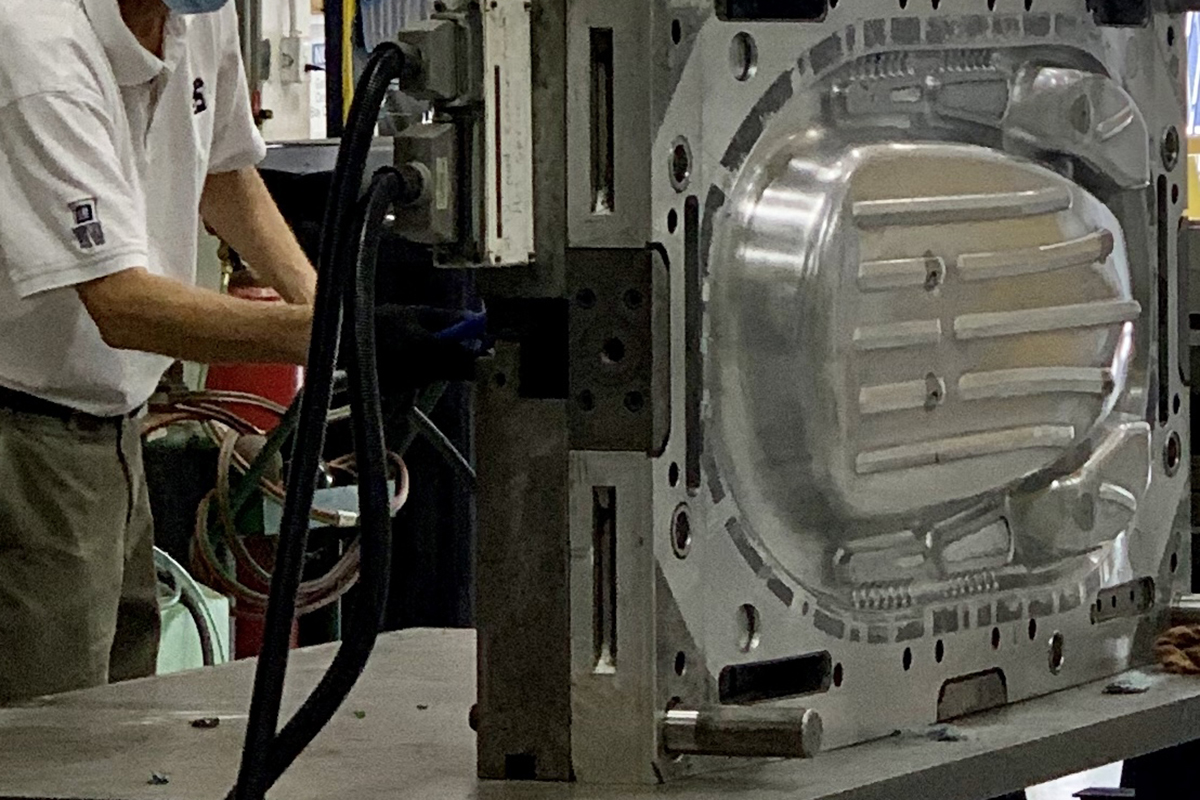

We openly collaborate with our clients directly to optimize product design and assist in product development. We employ Unigraphics® and MoldFlow® analysis for all products during the development stage. This proactive approach allows us to identify potential concerns and make any changes prior to tool completion to ensure design purity, optimized performance and structural integrity in everything we develop.

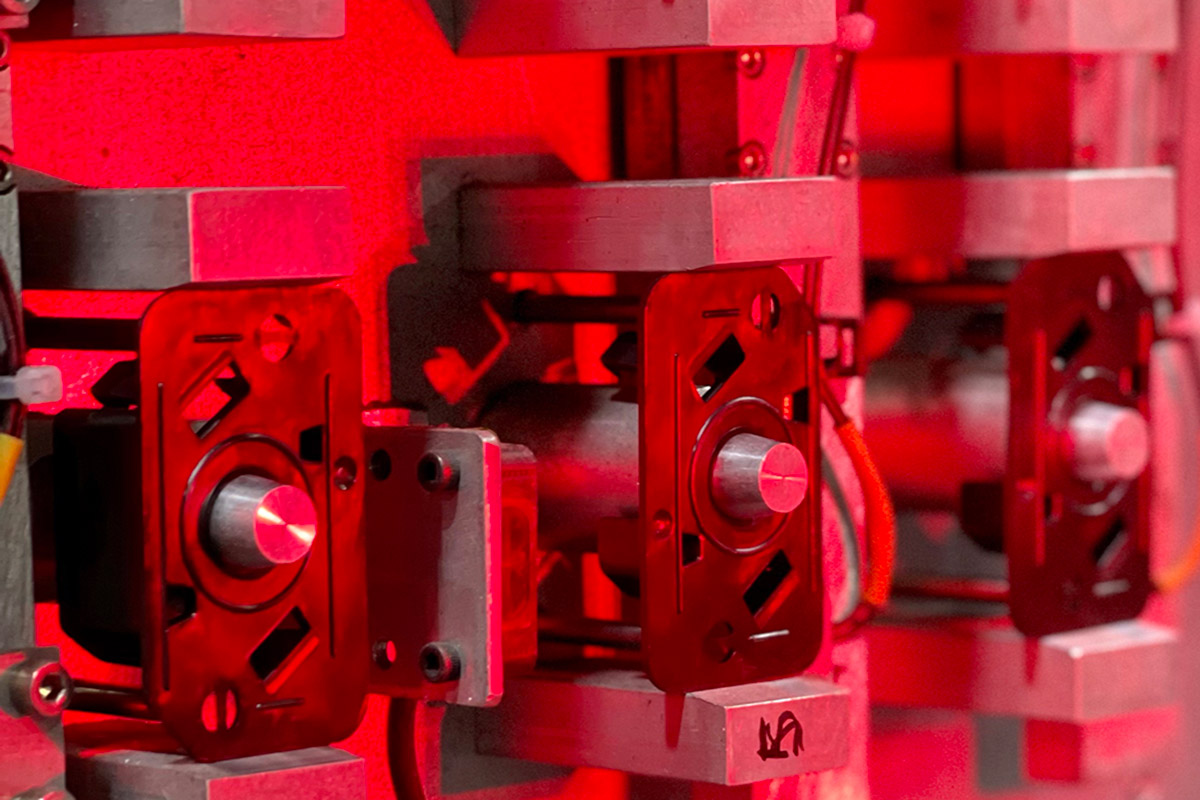

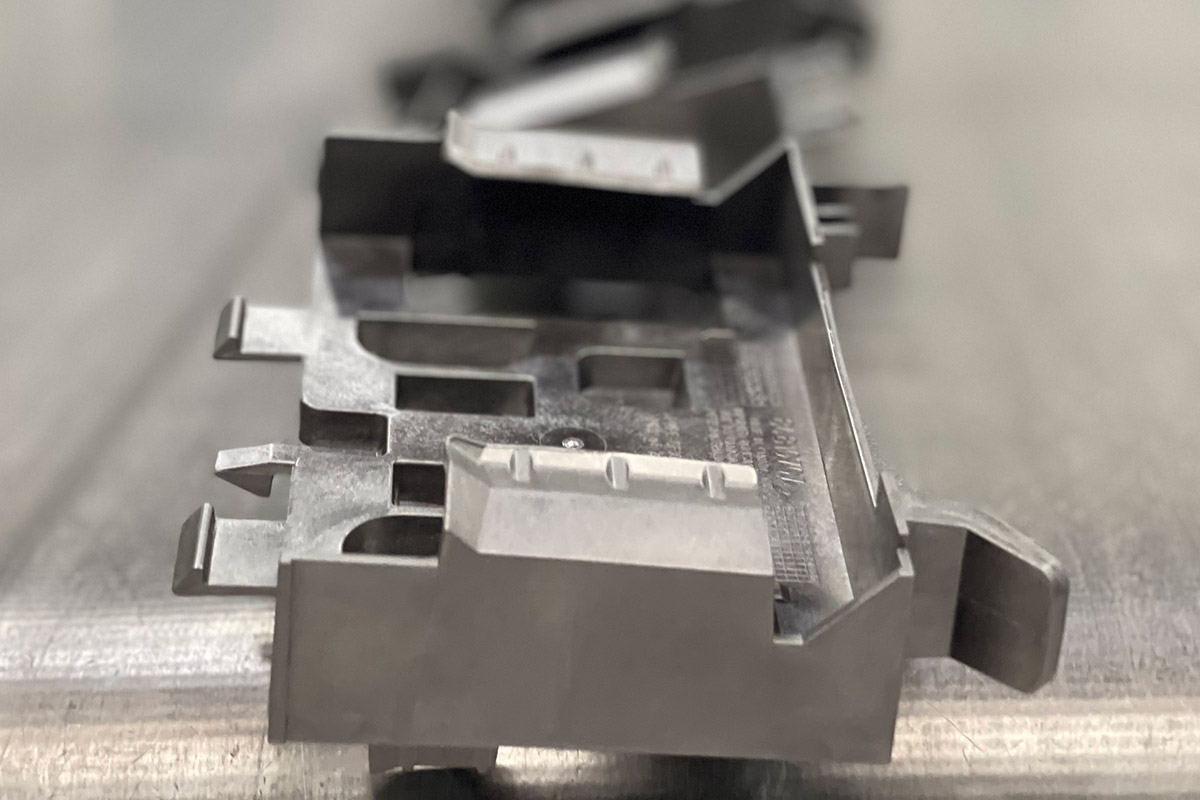

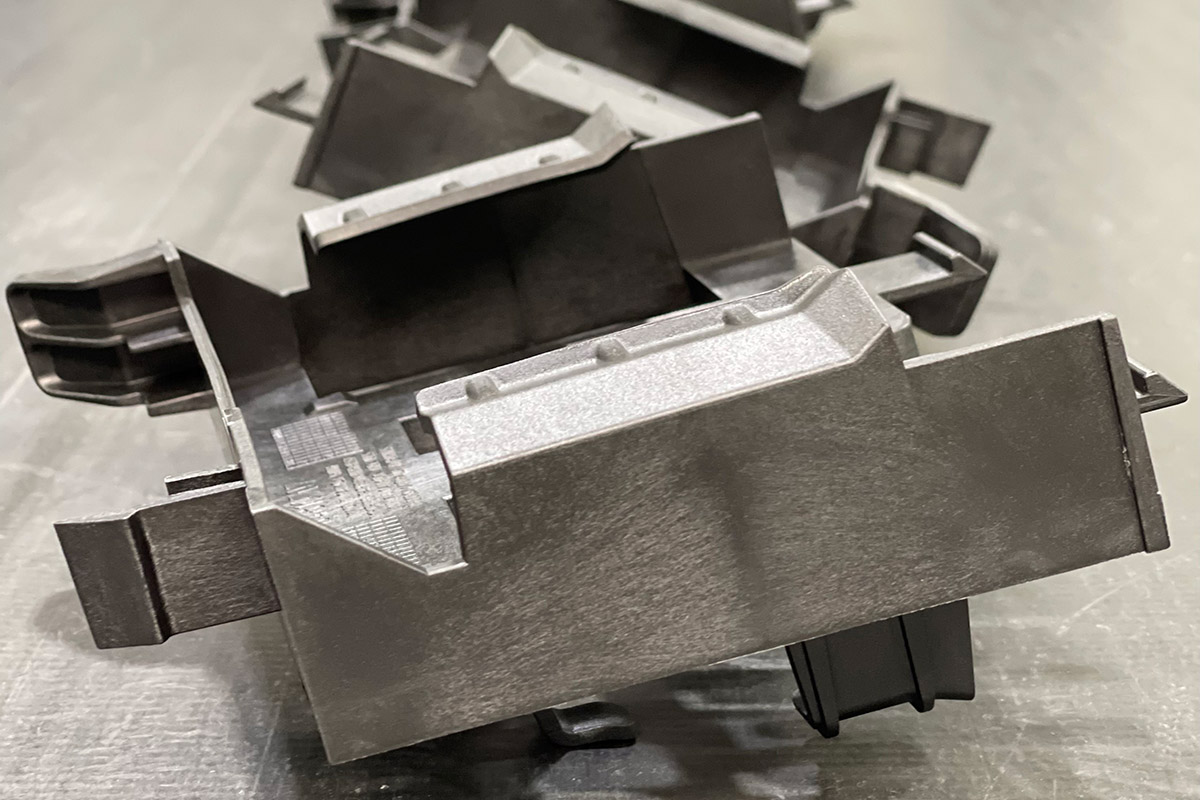

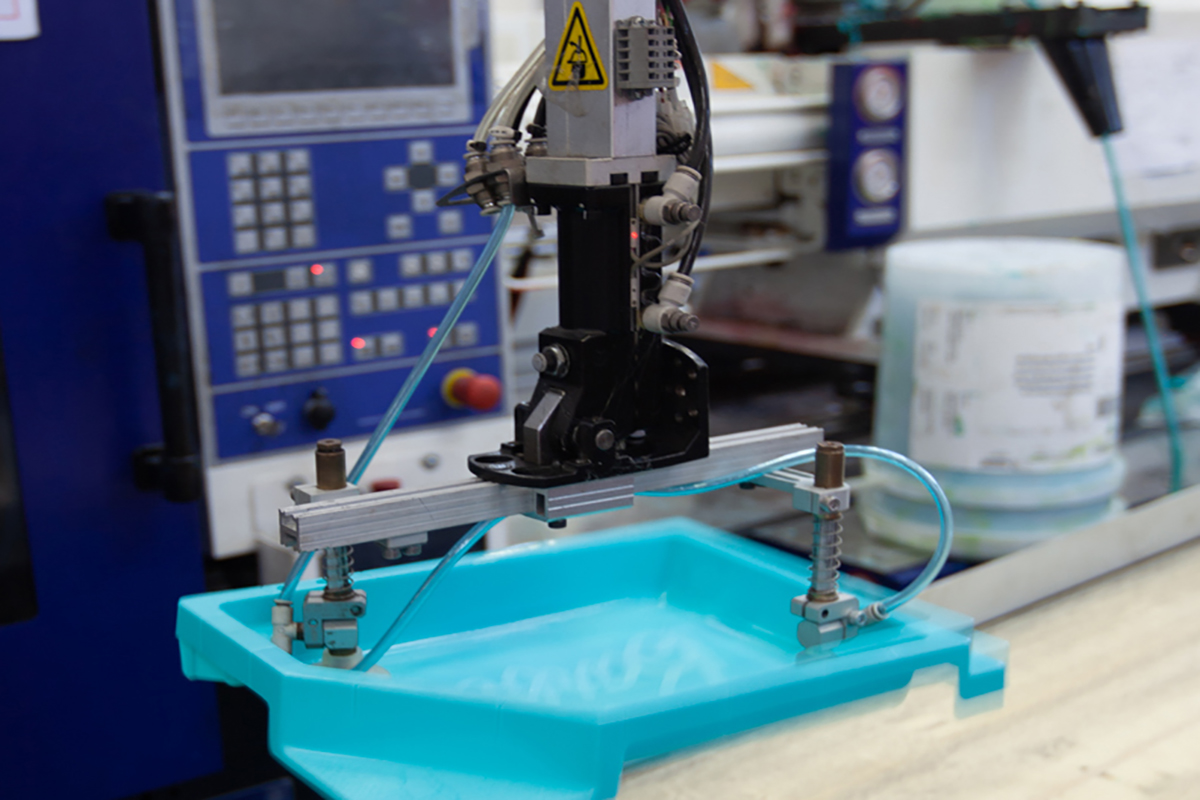

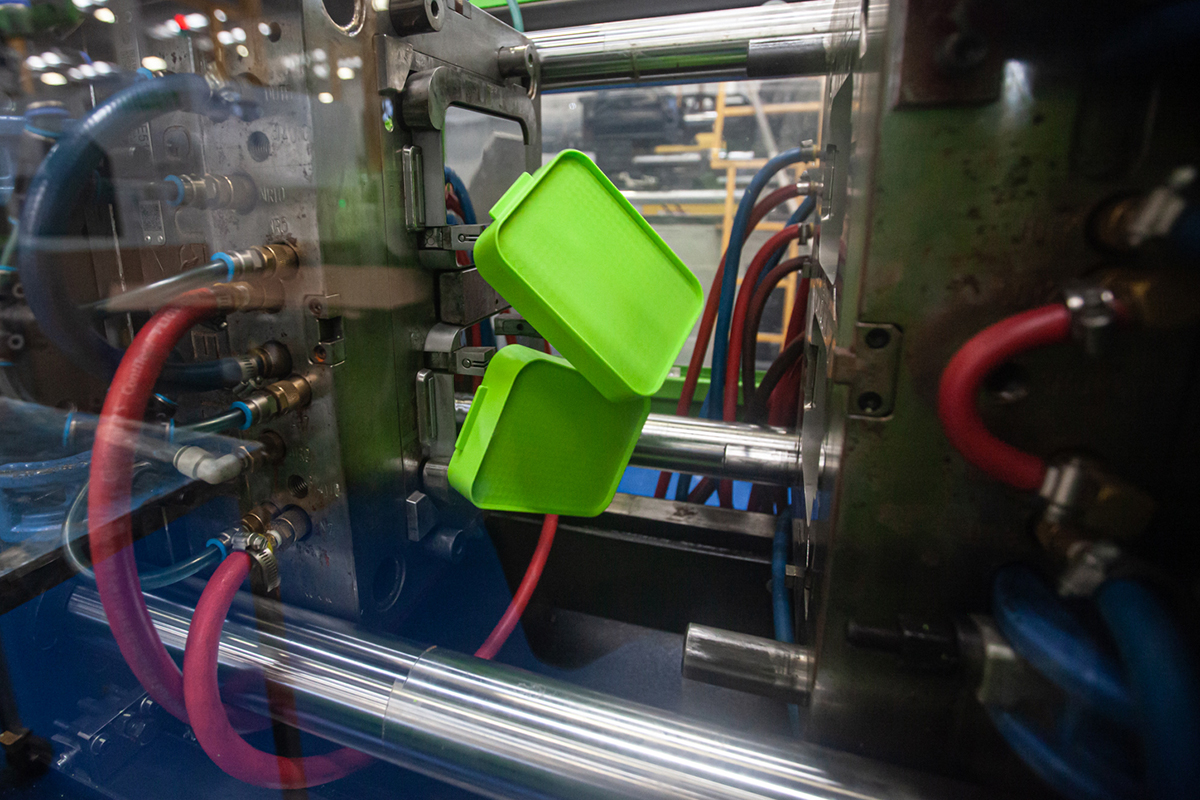

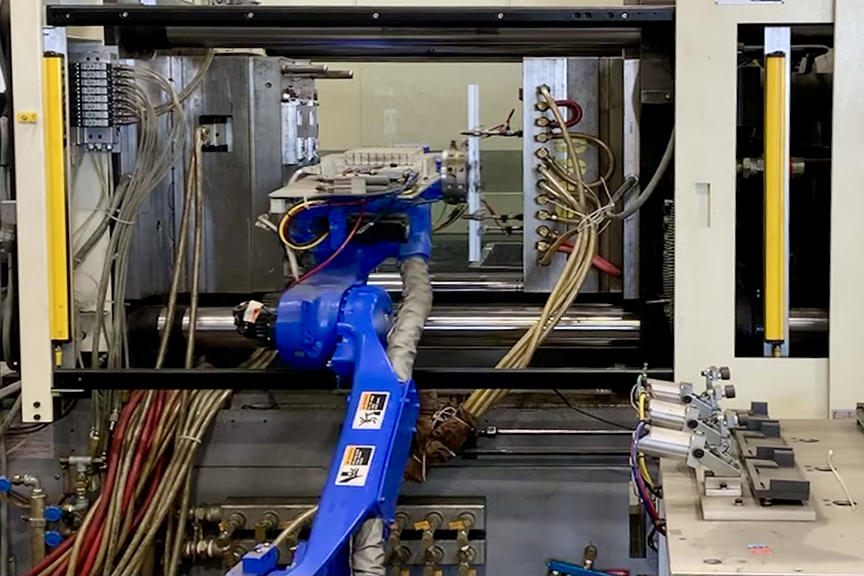

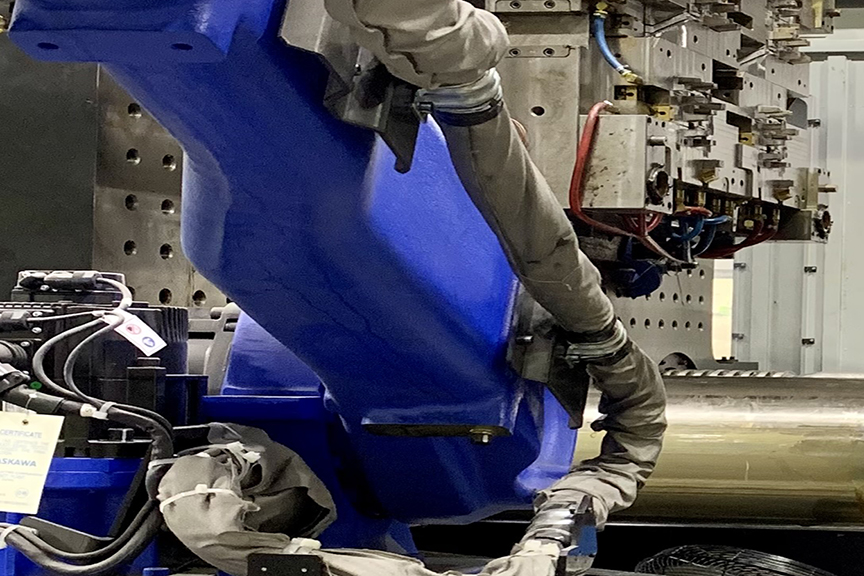

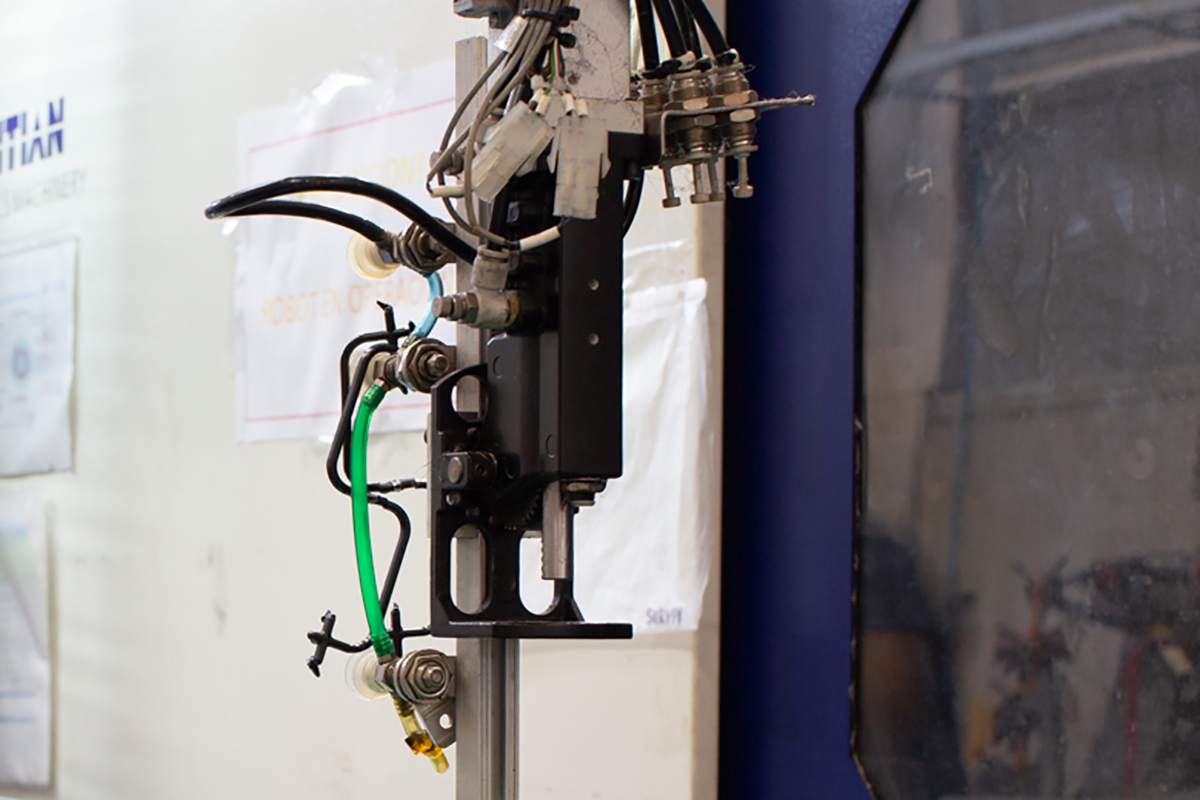

Our manufacturing processes include injection molding, insert molding, second-shot molding, valve-gate molding, heat staking, over-molding and sub-assembly. We also offer elite tooling management capabilities and ensure our tools are built and maintained to the highest quality standards.

Markdom has committed significant investments towards enhancing the company’s capabilities for even greater product innovation, manufacturing processes and business model optimization through dual-shot molding, under-hood systems, expanded insert molding, structural interior electronics and system integration.

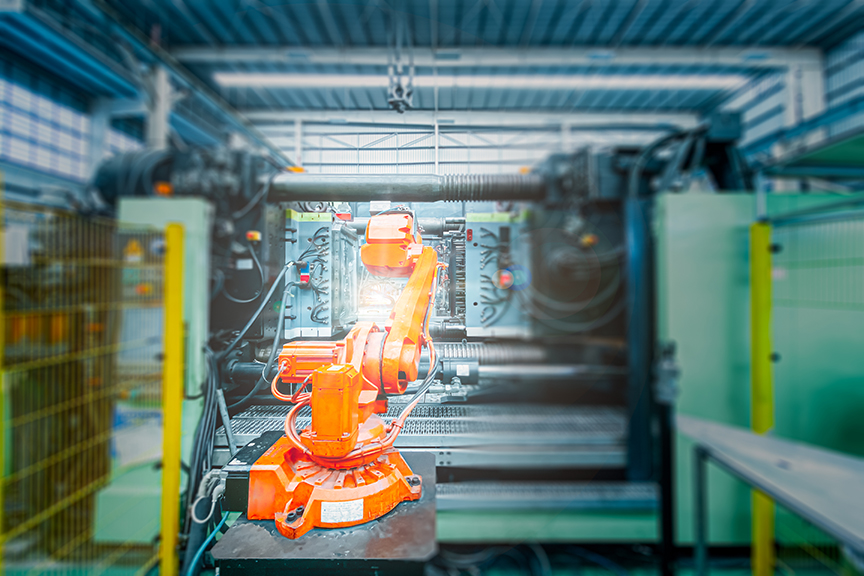

As we enter the stratosphere of Industry 4.0, we will be utilizing predictive analytics to prolong equipment life and leverage realtime data to forecast maintenance for fully optimized manufacturing processes.